As long as we're going to be begging for money to pay for traction motor rewinding, we might as well make it educational:

I recently bought a book called "Electric Car Maintenance" at our own IRM Used Book Store. Say, did we ever mention that the Used Book Store is a great place to shop? I even saw an article to that effect in Rail and Wire, so you know it must be true. Anyway...

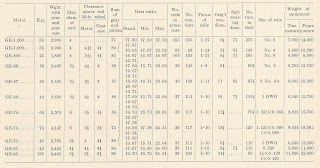

The book is a compilation of articles from old trade journals. Here's a very interesting table of useful data for GE traction motors, if you're into technical details. The GE-66 is the last row in the table on this page. Some of the columns are pretty obvious, but others require some comment.

First, we see that the maximum axle diameter is given as 5 3/4", but the CA&E cars have 6 1/2" axles. Maybe that's what puts the "B" in GE-66B motors. In the first few years, the CA&E was providing much faster service than anybody else, and they had problems with bent axles and broken gears. The actual gear ratios on the CA&E motors are either 20-32 or 25-40, since they needed bigger, stronger teeth than the table provides for.

The "No. coils in armature" is actually what I would call the number of poles. There are 39 poles and 39 slots, so five wires per pole gives 195 windings and therefore 195 commutator bars. The "throw of coils" is important if you're rewinding the armature. Basically, "1-10" means that each wire leaves a commutator bar through the first slot in one direction or the other; at the other end it then wraps around one fourth of a circle to the tenth slot and back to the commutator. Notice that the "throw" (in this case 10-1=9) is always equal to the "number of coils" divided by 4, rounded down. (This will be on the test.)

For some of the motors they give a "safe wearing diameter" of the commutator. For the GE-67, for instance, they in effect say that you can safely wear down the commutator bars by more than 3/4". I find that hard to believe, but in any case we're never going to run the cars enough to find out!

Finally, the GE-66 is wound not with wire, but with copper bars 1" x 1/8" that are specially formed and bent. All of these bars will need to be rewrapped with new insulation. I would expect that the winding bars should be OK; we know that in one place several of the commutator bars were melted away right down to the axle when the short-out occurred, so they need to be replaced. That, among other things, is what makes this such an expensive proposition.

No comments:

Post a Comment

Please identify yourself with a name of some sort in your comment. Completely anonymous comments will be deleted. Thanks!